Product Description

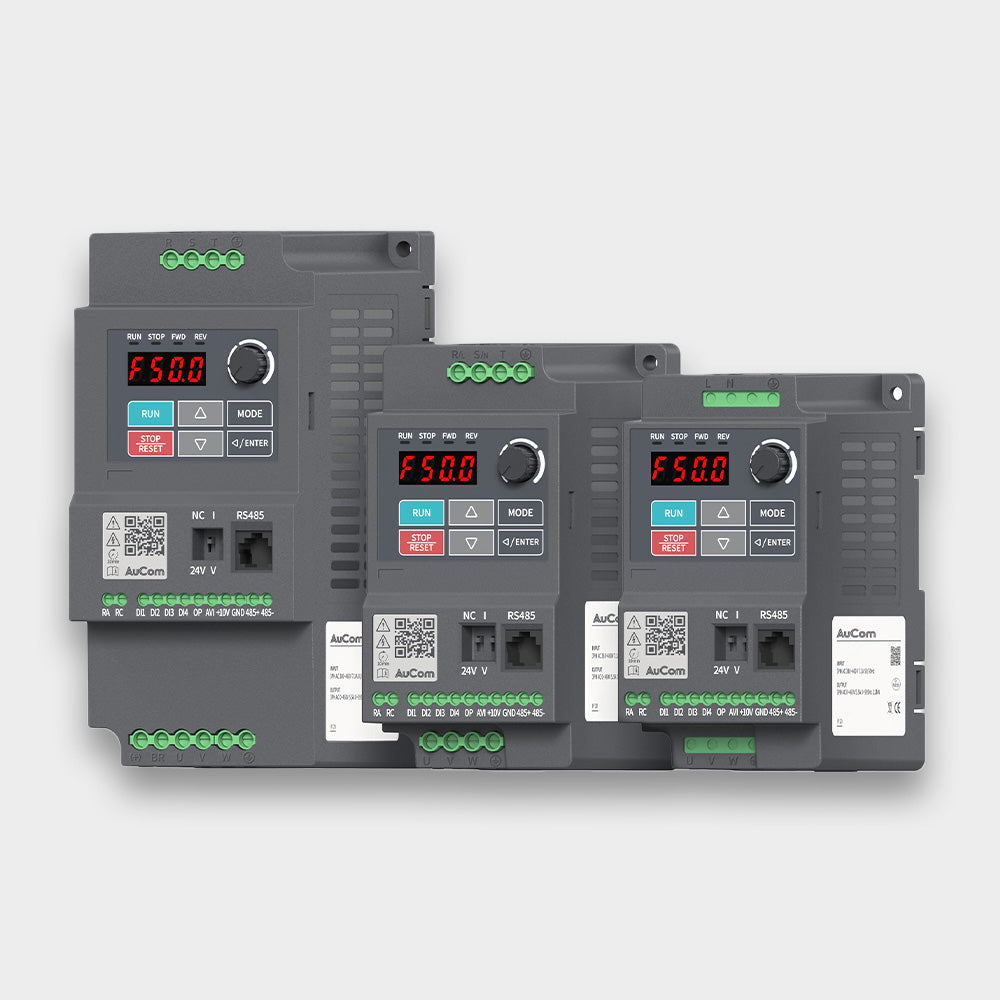

AuCom H1 LV-Micro Drive -a smart, compact, and highly reliable inverter designed for precision motor speed regulation.

Engineered for three-phase AC asynchronous motors, this versatile drive is ideal for industries such as food & beverage, logistics, packaging, textiles, and woodworking machinery. Its rich software and hardware configuration ensure superior performance, efficiency, and ease of use.

Features & Accessories

Starting Functions

- Constant current

- Current Ramp

Control Functions

- Rotational Speed Control (High and Low Speed)

- Pressure Control

- Position Control

- Synchron Motor Control

Protection

- Motor overload

- Overvoltage protection

- Undervoltage protection

- Phase loss

- Excess start time

- Phase sequence

- Current imbalance

- Power circuit fault

- Supply frequency

- Instantaneous overcurrent

- Bypass overload

- Communications failure

Interface

- Fixed relay output (main contractor relay)

- Programmable relay (trip or run)

- Run relay output

Accessories (Optional)

- Remote operator

- Modbus

- Profibus

- DeviceNet

- PC Software

- Ethernet/IP

- Modbus TCP

- Profinet

Specifications

Mains Control Functions

| Maximum Output Frequency | 599.00 Hz |

| Input frequency resolution | Digital setting: 0.01 Hz; analog setting: maximum frequency x 0.025 % |

| Carrier frequency | 7.5 kW and below: 2 kHz–15 kHz |

|---|---|

| 11 kW–93 kW: 2 kHz–10 kHz | |

| 110 kW–450 kW: 2 kHz–6 kHz | |

| Automatic carrier frequency adjustment can be done according to the load characteristics | |

| Starting torque | SVC: 150 %; FVC: 180 % |

| Speed regulation range | SSVC: 1:200; FVC: 1:1000 |

| Speed stability accuracy | SVC: ≤ ±0.5 %; FVC: ≤ ±0.3 % |

| Torque response | STorque step response < 20 ms |

| Overload capacity | 150 % of rated current (60 s) |

| Torque boost | Automatic and manual torque boost modes are included |

| V / F curve | Multi-point V / F curve; 1.5-power V / F curve; square V / F curve |

| Acceleration and deceleration curve | Linear or s-shaped acceleration / deceleration modes: there are four groups of acceleration / deceleration time values. Acceleration / deceleration time range: 0.00 s–600.00 s or 0.00 s–6000.00 s. |

| DC braking | Start DC braking and shutdown DC braking are included (0.00 s–60.00 s) |

| Jog control | Jog frequency range: 0.00 Hz–599.00 Hz; Jog acceleration / deceleration time range: 0.00 s–600.00 s or 0.00 s–6000.0 |

| Tension control | Four control modes are included: tension closed-loop speed mode,linear speed closed-loop speed mode, tension closed-loop torque mode and tension open-loop torque mode |

| Multi-speed running | Start DC braking and shutdown DC braking are included (0.00 s–60.00 s) |

| Built-in PID | Can easily realize closed-loop process control |

Operation

| Frequency sources | Multiple frequency setting sources: operation panel setting, analog setting,control terminal setting, communication setting, etc. |

| Auxiliary frequency sources | Multiple auxiliary frequency sources: operation panel setting, analog setting, control terminal setting, communication setting, etc.; auxiliary frequency fine tuning and synthesis can be flexibly realized |

| Universal terminals | 8 DI terminals (one high-speed terminal), three DO terminals(one high-speed terminal), and 2 relay output terminals. 3 AI terminals (one supporting PT100), 2 AO terminals, 2 STO terminals and 1 RS485 terminal. |

| Automatic acceleration / deceleration) | Automatic acceleration / deceleration time adjustment based on the load torque |

Product Standards

| Applied safety standard | IEC61800-5-1:2007 |

| Applied EMC standard | IEC61800-3:2005 |

| EMC Filter | All VFDs are built in line to IEC/EN 61800-3 category C3 |

Personalized Functions

| Peripheral safety self-test | A safety test is performed on the peripherals to timely identify any problems, such as a grounding problem or a short-circuit and improve the reliability of the system |

| Common DC busbar function | A common DC bus can be shared by multiple VFDs |

| JOG key | The JOG key on the operation panel can be used for jog running |

| Fast current limiting function | A quick current limiting algorithm is embedded to reduce the probability that an overcurrent fault happens to the VFD |

| Motor parameter identification | Automatic motor parameter identification |

| Standardized panel extension cable | A constant voltage output can be maintained in case of grid voltage variations |

| Communication buses | At least six kinds are supported (Modbus, Profinet, CANopen, Profibus-DP, EtherCAT and Ethernet) |

| Expansion function | I / 0 expansion card; bus communication expansion cards; PG cards (incremental sin / cos encoder cards) |

| STO | Safe torque off in case of emergency |

| Inductors | VFDs ≤ 45 kW have no integrated inductors |

| VFDs ≥ 55 kW have an integrated DC inductor in the standard configuration | |

| VFDs ≥ 200 kW an integrated output AC inductor can be selected as an option | |

| For all H1-Series devices several types of external inductors are available on request | |

| Braking Resistor | VFDs ≤ 30 kW have an integrated brake-unit in the standard configuration |

| VFDs 37 kW to 132 kW an integrated brake-unit can be added as an option | |

| For all H1-Series devices external brake units are available on request |

Environment

| Use place | Indoor, free from direct sunlight, dust, corrosive gas, flammable gas, oil mist, water vapour, dripping water or salt, etc. |

| Altitude | ≤ 2,000 m ASL; 1 % current derating for every 100 m above 1000 m ASL

The maximum application elevation is 3,000 m; when the elevation is higher than 3,000 m, contact the manufacturer 2 % derating for every 1°C above 40°C; > 50°C contact the manufacturer |

Humidity | < 95 % (RH), w / o water droplets |

| Vibration | < 5.9 m/s2 (0.6 g) |

| Storage temperature | -20°C~+60°C |

| Pollution degree |

No electrically conductive dust permitted.

Cooling air must be clean and free from corrosive materials.

Chemical gases, class 3C3. Solid particles, class 3S2. Painted circuit boards as standard. ( according to IEC 60721-3-3) |

Display and panel operation protections and options

| LCD display | English, German and Spanish are supported |

| Operating altitude | 0 - 1000 m, above 1000 m with derating |

| LCD parameter copying | Quick parameter copying can be accomplished on the LCD panel |

| Protection functions | Motor short-circuit detection Input / output phase loss protection Overcurrent protection Overvoltage protection Undervoltage protection Overtemperature protection Overload protection |

| Options | Brake assembly |

Ressources / Downloads

Product Advantages

AuCom - Driving Motion

“Reliability that drives our success”